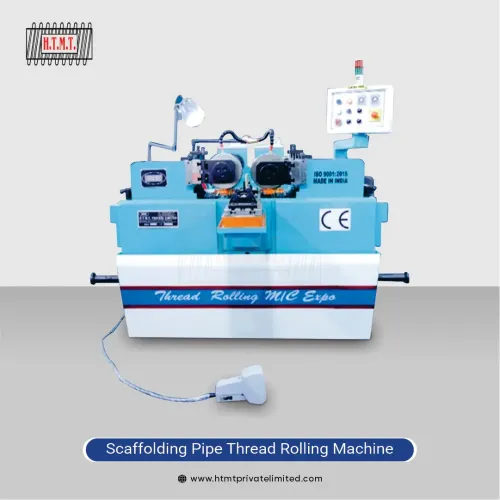

When it comes to construction, no structure can stand confidently without strong scaffolding support. And this is where Scaffolding Machine Manufacturers in india come into play. These machines are designed with precision, stability and long-term durability to enable construction companies' to work quicker and safely. Over the years, the demand for innovative scaffolding systems has grown tremendously and therefore, the focus of modern manufacturers is on manufacturing machines that will eliminate the need for manual operations and facilitate improved alignment and increased production efficiency.Whether it’s for large real-estate projects, bridges, towers, metro infrastructure, or industrial plants, scaffolding machines have become a backbone for smooth and safe operations.

One thing that sets these machines apart is their ability to maintain uniformity even in bulk production. Today, construction companies don’t just look for machines—they look for reliable machines that can handle high workloads without compromising quality. And Indian manufacturers are known for delivering exactly that. From cuplock systems to props, ledgers, and frames, every product depends heavily on the accuracy of these machines. That’s why manufacturers focus deeply on machine stability, spindle quality, roll design, and long-term performance to ensure that every component produced can withstand real-life site conditions.

Understanding the Real Role of Scaffolding Machines

Scaffolding machines are machines that automate the fabrication processes for scaffolding parts including, shaping, rolling, cutting and welding. They are designed to provide consistent dimensions, reduce human error and greatly accelerate production. In comparison to manual production of scaffolding pieces, most manufacturing facilities have converted their production from manual production of scaffolding pieces to Automated Scaffolding Systems (ASS), which creates thousands of scaffolding components accurately and uniformly on a mass scale.

The primary benefit of using an automatic scaffolding machine is improved worker safety. Since scaffolding components are to be designed to withstand certain weights, then they must be manufactured with the same strength; otherwise, the safety of workers on-site is compromised.

Types of Scaffolding Machines

Below is a detailed understanding of the major scaffolding machines used across India:

1. Cuplock Welding Machine

A cuplock welding machine is designed to create perfectly aligned cup joints required in cuplock scaffolding systems. these machines enable the manufacturer to maintain exact spacing between cups on the vertical pipe of a cuplock scaffolding. To ensure accurate placement, it is crucial that the welding of the cups occur at predetermined points along the vertical pipe. Accurate placement is crucial because most of the time cuplock scaffolding is used for large projects with many stories and where the stability of the structure is of utmost importance.

Key Functions:

- Ensures welded cups are perfectly centered

- Helps produce vertical standards efficiently

- Reduces human errors in welding

- Increases production speed

2. Ledger Forming Machine

This machine is used to create ledgers, which are horizontal components in scaffolding systems. The machine forms and shapes ledger blades so they can fit securely into the cuplock cups. With constant load-bearing requirements on construction sites, the ledger forming machine ensures uniformity in size and shape for maximum safety.

3. Ringlock Scaffolding Machine

A ringlock scaffolding machine manufactures verticals, horizontals, and rings with high precision. Ringlock systems are known for their superior load capacity and installation speed, so their machine design focuses on accuracy and stable mechanical strength.

4. Pipe Cutting & End Forming Machines

These machines cut scaffolding pipes to exact lengths and shape the ends for further welding. They ensure smooth edges, perfect cuts, and consistent pipe lengths across large batches—something that is essential for safe scaffolding assembly.

5. Hydraulic Rolling Machines

These machines are used for shaping pipes and components under high pressure. They offer uniform rolling strength and can handle heavy-duty operations for large-scale scaffolding manufacturing.

Scaffolding Machine Suppliers in India – Trusted Choice for Quality Machines

The connection between manufacturers and businesses that need scaffolding equipment is provided by suppliers. Scaffolding Machine Suppliers in India provides customers with the added benefit of guidance in choosing the right equipment, assistance after the sale with installation; and availability of spare parts when needed.

When companies begin their search, they often look for the overall scaffolding machinery range. This type of equipment is the most commonly used equipment for every step (handling, welding, rolling, threading, shaping, and assembling) required to manufacture scaffolding components. Choosing a Supplier is very important; the Supplier you choose must provide the highest quality Machine(s) (i.e. machinery that is accurate, durable and safe) available. A knowledgeable Supplier will work with you to determine what type of Machine will best suit your needs (including the Machine size and design required by your production efficiency) and future business requirements.

Unique Benefits Offered by Suppliers

- Deep knowledge of local construction demands

- Machines compatible with Indian-grade steel

- Competitive pricing with high-performance output

- Easy availability of spare parts and accessories

- Strong after-sales support

They ensure that every buyer—from small workshops to large industries—gets a machine that delivers consistent output and long service life.

Scaffolding Machine Dealers in India – Your Reliable Scaffolding Machine Partner

The connection between the dealer and the supplier is made by having a dealer who provides personalized service, onsite demonstrations of the equipment, and at the time of equipment installation, directly assists with the set up of the machine for the end-user. An understanding of the impact of timely service is critical to businesses’ ability to hold to deadlines on large projects by Scaffolding Machine Dealers in India.

Dealers will instruct buyers on how to achieve operational efficiencies while reducing production errors and by providing quick ROI (Return on Investment). The goal of all dealers is to keep machines working without the hindrance of unnecessary downtime.

Budget-conscious companies are frequently looking to determine the scaffolding machine price . Dealers are able to provide support in comparing models of equipment based on their features, levels of automation, durability over the long term, and as such, allow businesses to purchase machinery that is in alignment with the company's budget, without compromising safety or the quality of output.

Dealers generally represent several different brands of scaffolding equipment, which allows for a user to select between models based on various criteria, such as types of automation, production capacity, energy usage, material compatibility and maintenance requirements.

Why Dealers Are Important

- Quick access to machine parts

- Onsite support during machine installation

- Operator training and handling guidance

- Easy machine upgrades and model recommendations

- Flexible purchase options

Their presence in the market helps industries adopt new technologies faster.

Scaffolding Machines Exporters in India – Delivering Performance Worldwide

Scaffolding Machine Exporters in India have created a good reputation for providing machinery that is strong, durable and cost-effective by international standards. Their machinery is globally utilized on mega project sites, industrial manufacturing facilities and infrastructure development locations.

Exporters also ensure machines are tested under strict quality-control parameters before being shipped. This guarantees that global clients receive machines that can operate smoothly under tough working conditions.

For clients looking for advanced cuplock machinery, exporters offer scaffolding cuplock machines that come with high accuracy, superior welding strength, and long-term performance. These machines help international companies build safer and more reliable scaffolding components for major construction projects.

Applications of Scaffolding Machines

Scaffolding machines support a wide range of applications, such as:-

- Construction Projects: High-rise Buildings, Residential Complexes, Metro Stations

- Industrial Structures: Refineries, Power Plants, Ship Yards

- Infrastructure Projects: Bridges, Flyovers, Tunnels

- Maintenance Jobs: Painting, Repair Work, Cleaning of Tall Buildings

Every component manufactured using these machines directly contributes to safety, load capacity, and structural stability of scaffolding systems.