HTMT Pvt Ltd designs and manufactures machines that meet real industrial needs. Our Thread Rolling Machines and Scaffolding Systems are built for long hours, smooth operation, and consistent performance even under heavy workloads. We focus on practical, user-friendly design. Machines are simple to operate, require minimal maintenance, and deliver stable output for every workflow. HTMT has been a trusted partner of various industries both in India and internationally due to its long-life cycle, high-efficiency products, and increased productivity through our innovative system solutions. With the expert guidance of our highly trained staff, combined with superior installation methods and robust design.

Read More

Explore our products, which are made to work well and last long. They are strong, reliable, and help to make your work easier and faster, ensuring you achieve excellent results every time

A Thread Rolling Machine is an advanced industrial machine used for producing high strength and highly accurate threads on metal components through a cold forming process.

Read More

Our recommendations are based on field performance, component quality, and their operational simplicity, so that every machine matches your industry needs.

Read More

A Spline Rolling Machine is a precision forming machine used to produce strong and accurate splines on metal shafts through a controlled cold forming process. Instead of cutting the materia

Read More

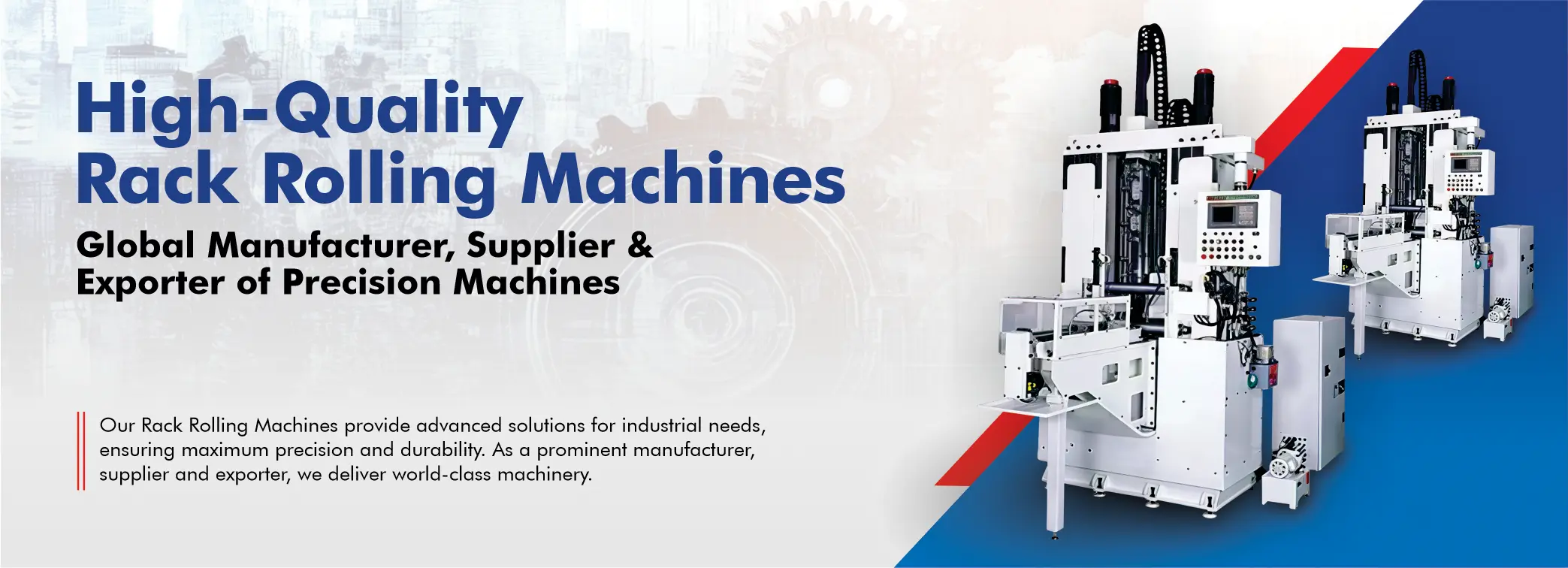

A Rack Rolling Machine is a precision engineered cold forming machine used to produce high accuracy gear racks, spline racks and threaded rack profiles for various industrial applications.

Read MoreOur manufacturing process follows a clear, quality-focused method where every step is carefully checked. HTMT ensures accuracy, durability, and smooth machine performance so each machine works reliably, even in tough and heavy industrial conditions.

Read the storyQuality Assurance

Skilled Professionals

Years of Expertise

Projects Completed

Being one of the most reputed Thread Rolling Machine Manufacturers In India, HTMT Pvt Ltd is a company that has established its reputation in producing machines with high accuracy, extended service in the industry, and easy industrial running. Their machines are made using robust materials and engineering, which also makes them have the same thread quality even when using heavy production. Each of the models is designed to be stable, durable, and precise, hence applicable to both large and small production units. The company also keeps the thread rolling machine price practical for different industries, offering strong value and dependable performance.

Why HTMT Pvt. Ltd. Stands Out as a Manufacturers

Their manufacturing standards make them a preferred choice across India.

As one of the leading Thread Rolling Machine Suppliers In India, HTMT Pvt Ltd focuses on providing machines that are durable, easy to operate, and engineered for consistent output. Their supply network ensures fast delivery, complete installation assistance, and clear guidance for every machine model. The company supports industries with machines that run smoothly with minimal vibration, giving stable thread formation and long tool life.

Their team always helps customers select the best model for their work requirements. Whether a business needs a basic manual setup or a more advanced solution, HTMT Pvt Ltd provides honest guidance. Their machines are designed for easy handling, making thread rolling machine manual operations simple and controlled for operators at every skill level. This makes them ideal for workshops and factories that require flexible production without complex automation.

This supplier strength makes the company a preferred partner for industries across India.

As dependable Thread Rolling Machine Exporters In India, HTMT Pvt Ltd delivers machines that meet global quality standards. Every export unit undergoes strict performance checks—from roller alignment to pressure control—to ensure maximum accuracy and longevity. This is why international buyers trust their machines for large-scale production needs.

The company offers strong export packaging, secure shipping, and complete documentation support. Before dispatch, each machine is tested for thread precision, body strength, and long-run stability. This makes their machines ideal for industries searching for thread rolling machine india solutions with long-term reliability.

Their machines deliver more value compared to many global brands, providing stable output, higher accuracy, and long service life. This balance of quality and pricing helps the brand maintain strong international relationships.

As trusted Thread Rolling Machine Dealers In India, HTMT Pvt Ltd ensures customers experience fast service, easy machine availability, and expert in-person guidance. Their dealer network supports buyers with honest recommendations, machine demos, spare parts, and direct assistance. This makes the purchasing process smooth and stress-free for industries of all sizes.

Dealers help customers understand machine features, threading capacity, roller selection, and ideal model configuration. Anyone searching for thread rolling machine near me often finds HTMT Pvt Ltd dealers at the top because they offer clear communication, genuine knowledge, and quick solutions.

Why Their Dealers Are Highly Preferred

Dealers also assist with troubleshooting, operator training, and proper machine setup, ensuring customers get maximum performance from day one. Their transparent approach and reliable service make them a trusted option across the Indian industrial market.

Thread Rolling Machines use a cold-forming technique to create threads without cutting any material. Instead of removing metal, the machine uses high-pressure rolling dies that press against the workpiece and reshape it into the exact thread design. This method creates stronger, smoother, and more accurate threads compared to cutting.

It starts with inserting the metal bar into two die designs. The die turns and pressure causes the metal to be forced into the grooves and creates clean uniform threads. Such compression makes the material stronger and more durable.

Key Advantages

Steps of the Process

This combination of precision, pressure, and speed makes thread rolling the preferred choice for industries needing high-strength, high-accuracy threading.

HTMT thread rolling machines are designed with advanced features that improve performance, accuracy, and user convenience. Each machine includes high-strength rollers, stable frames, and energy-efficient components to ensure smooth operation. They are flexible and can accommodate various types and sizes of threads without a loss in uniformity and strength. These machines are suitable to every industrial operator due to safety measures, convenient controls, and minimal vibration. Sturdiness, accuracy, and efficiency are the qualities that enable HTMT machines to emerge as the main choice in the industries that want to invest in the threading solutions that are dependable over a long period of time.

Key Features:

To ensure quality performance and to increase the life of machines, it is important to maintain HTMT thread rolling machines. Rollers and moving parts are lubricated regularly to avoid wear and tear, and die alignment is regularly checked to maintain the precision of the threads. Washing the machine after the work shift minimizes the dust and debris. The operators are supposed to observe the pressure settings and roller condition to prevent thread defects. Replacement of parts due the wear and tear over time and use of actual HTMT spares saves quality and prevents sudden failures. These are easy maintenance procedures that will enable industries to get maximum productivity, minimize downtime, and ensure that their thread rolling machines yield maximum returns.

With years of experience, HTMT Private Limited provides strong, reliable threading and rolling machines, helping industries work with accuracy, speed, and quality in many engineering and manufacturing areas.

We create high-precision threaded parts and shafts for the automotive industry.

Our machines produce durable threaded components for heavy industrial equipment.

We produce threaded parts for pipes and fittings used in the energy sectors.

We manufacture threaded parts for tools and machinery used in construction.

We supply bolts, shafts, and components essential for power transmission systems.

We ensure precise threading on rods, shafts, and various metal components.

Our solutions help workshops easily produce and repair threaded parts.

We provide strong and accurate threaded components for various engineering projects.

We offer precise threaded parts for a wide range of metal fabrication needs.

We Appreciate Your Feedback!

It’s normal to have questions when choosing the right machine for your work. This section helps you understand our process, product features, and support services in a clear and simple way. If you need more help, our team is always here to assist you.

HTMT meets global demands when it comes to supplying the best quality thread rolling machines. These machines are durable and serve industries across various sectors. HTMT is one of the leading thread rolling machine suppliers in India. The platform is preferred for supplying products that have:

Read More